Thermal Video links for FloEFD and Solidworks Flow Simulation

Karim Segond as Speaker:

Power-Point presentations on request

Importance of Simulation in Engineering Design

Short Youtube video

He explains in an interview the use of FloEFD for his engineering consultancy.

Cooling calculations of transformers and inductor coils

Power Electronics Cooling Calculation at Room Level

recorded webinar

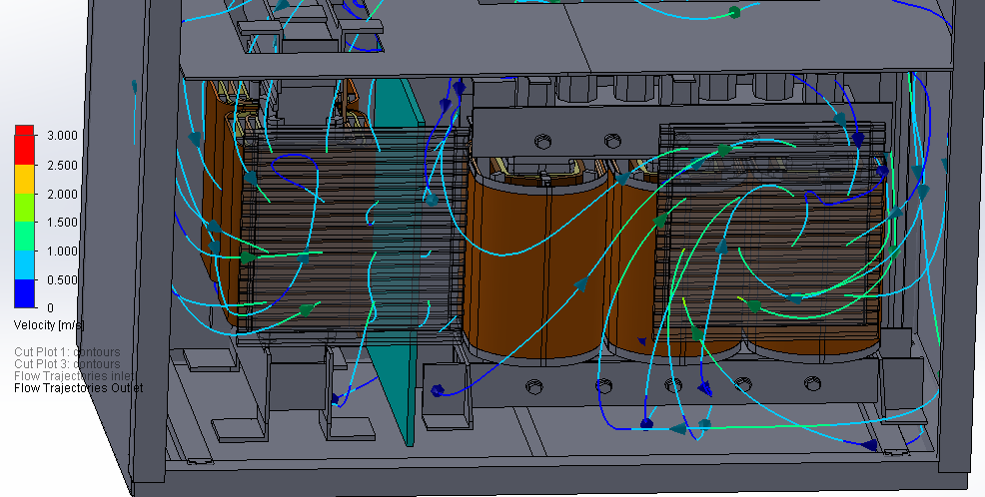

The meaning of the Room Level is explained. The working point of the fan can be evaluated using CFD calculations. The heat transfer is not calculated for reasons of cost

and because the electrical losses are insufficiently known. The ventilation of the components is evaluated using the streamlines, the flow vectors and the pressure distribution.

Thermal management of Power Electronics chips

Cooling of a Wind Power Station IGBT

recorded webinar.

The frequency converter and the IGBT chips need cooling, The value of the thermal resistance of the Thermal Interface

Materials influences the results. Set-up a transient case for low frequencies.

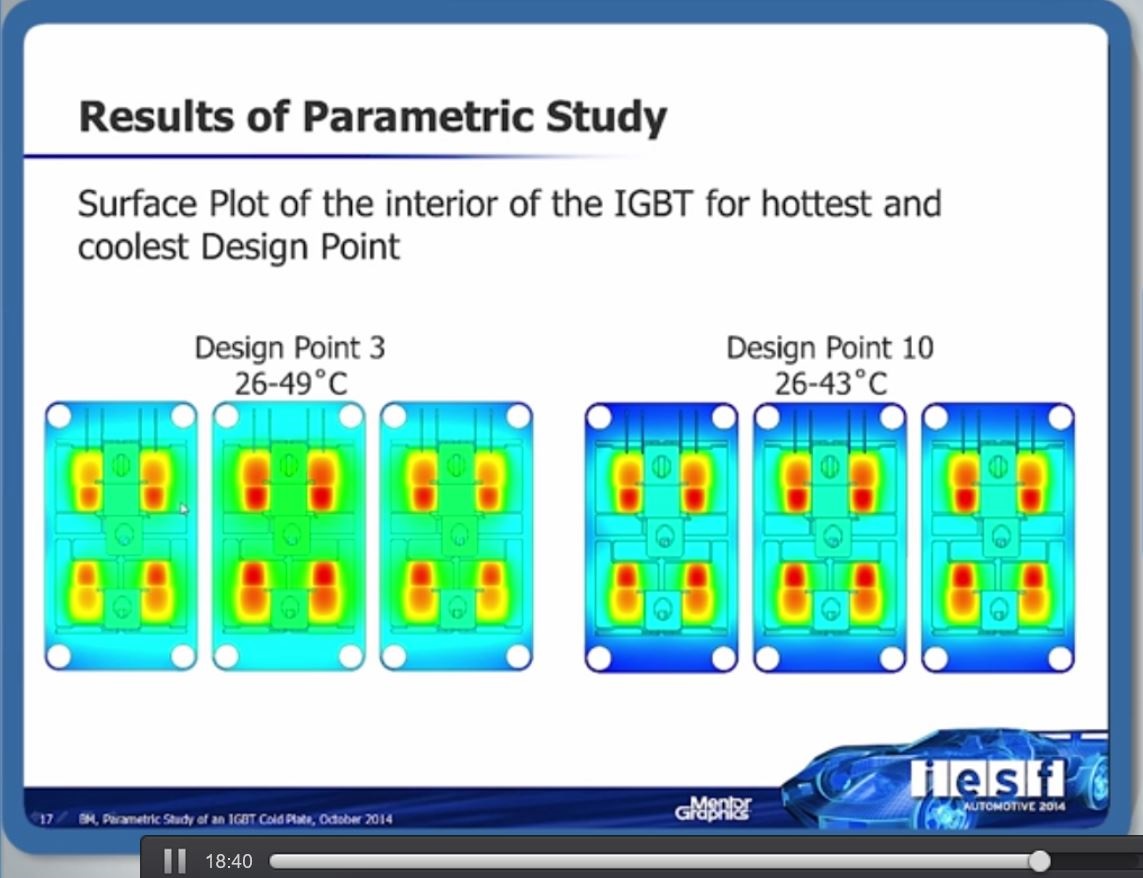

Parametric Study of an IGBT Cold Plate Geometry in a

Thermal Simulation

Two aluminum plates are connected with a heat sink made of pins or fins , in which optimal heat dissipation should take place. The design optimization is done with parameter variations in FloEFD for Catia with parallelization and full automation of the process. The size, number and height of the cooling fins are varied to avoid high pressure losses in the water circuit and to achieve high heat transfer with low weight.

Thermal and flow calculations for electric motors

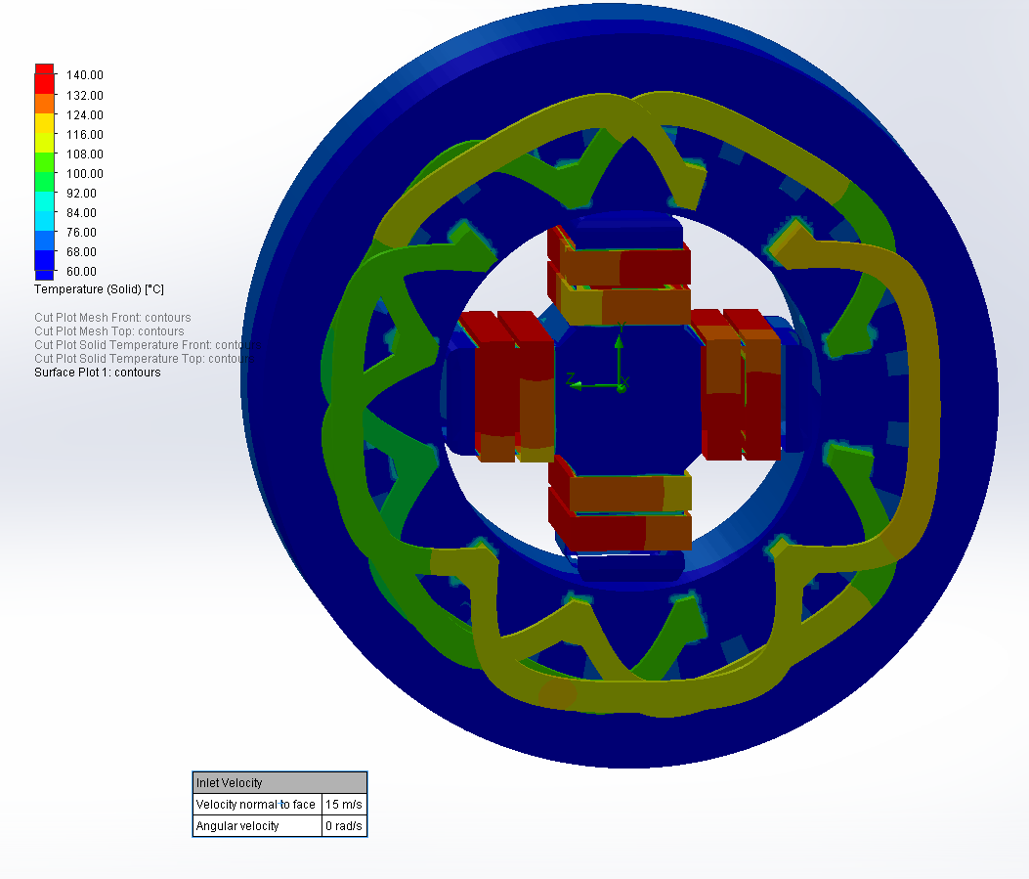

Winding Parameter Variations for the Cooling of an Electrical Motor

recorded during the Integrated Electrical Solutions Forum 2014 in Munich.

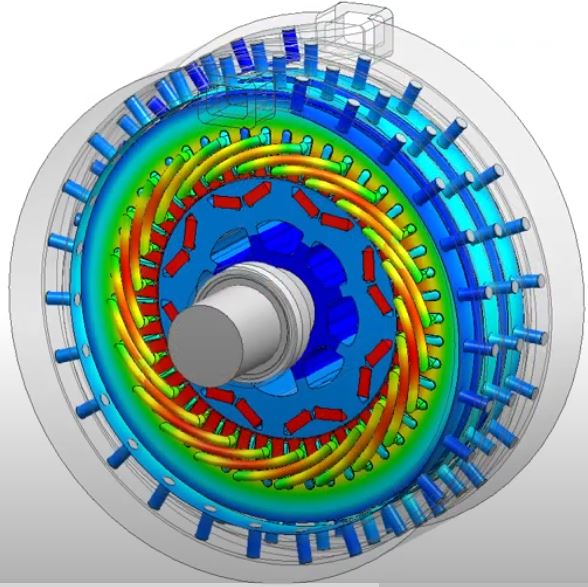

Different winding configurations have been calculated. The hairpin windings are modeled with copper bars and layers of insulation; the wire windings are simulated as anisotropic blocks with empirical values of thermal conductivity.

The highest temperatures are located and can be reduced. As a measure, the conventional insulation in the rotor and stator was replaced with high thermally conductive insulation.

Cooling of Electrical Machines

recorded webinar.

Large electrical machines (motors, generators and transformers) need cooling. It is explained how to set up a flow simulation with conjugate heat transfer (CHT) in FloEFD.

Optimization potentials and possible parameter variations are discussed.

CFD Design of a shaft-mounted radial fan for the cooling of an electrical motor

recorded for the "Realize live Europe 2022" conference in Berlin.

The examined 120 kW asynchronous motor has a completely closed cooling system. The fan is mounted on the shaft, it uses the rotation of the shaft and therefore does not need an external motor. To design the fan, it is important to fully model the fan with its blades and rotation. We will show the different methods for simulating rotation in Simcenter FloEFD. When the design of the fan is complete, a fan curve (volume flow versus pressure) can be drawn by varying the motor's flow resistance. For the detailed flow design of the machine, it is sufficient to simulate the fan with its curve.

3D CFD Flow simulations

Hydraulics

Physical considerations

3D CFD Mesh

CFD Calculation model

CFD Calculation programs

Electrical Machines

Cooling large motors

Cooling medium motors

Electrical calculations

Cooling calculations of motors and generators

Cooling of power electronics

Cooling of IGBT at low frequencies

Electrical cabinets

CFD Engineer Consulting

Karim Segond

Videos of Segond

Heating, Ventilating and Air Conditioning with CFD

Privacy Policy