Large alternative current machines are used as drives for large industrial plants or as generators for the net power generation. Large direct current motors are still used in few old rolling mills and factories.

The asynchronous and synchronous rotating electrical machines have the same stator composition: a wound stator core composed of core sheet layers embodies grooves in which copper layers are regularly placed throughout the circumferential extent. The winding coil is isolated according to the its voltage and isolation classes. These copper layers are connected in three phase-windings. The parts of the winding emerging from the stator core, also called core ends, are connected through a terminal box to the electrical network. The core ends are supported by complex mechanics and reinforced among each other. This ensures that mechanical stresses do not provoke any deterioration even in exceptional situations. It is highly challenging to perform CFD-calculations for these geometries.

Coil end with distributed winding

Coil end with distributed winding

The asynchronous three-phase machines, also called induction machines have either squirrel-cage rotors or slip-ring rotors. Squirrel-cage rotors have grooves which are filled with non-isolated compact copper or aluminium stems which are short-circuited on each end by a ring. Slip-ring rotors have isolated windings that are connected to slip rings on the rotor shaft.

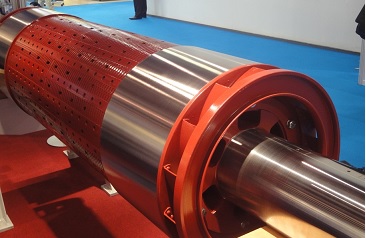

Synchronous machines have either a pole salient rotor or a cylindrical rotor. Pole salient rotors have fully developed poles with a magnetic core and coil windings. Cylindrical rotors are made from steel laminations, they incorporate groves in which isolated copper windings are placed according to a north and south pole connection. Cylindrical rotors are required for high rotational speeds due to their massive steel rotor. Both rotor types have windings exited with a DC current supply.

Turbo rotor with radial fan fixed on the shaft (older design)

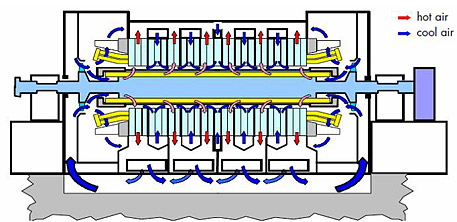

Large machines need a cooling concept with fans to force the cooling medium through the machine. The fans can be either externally driven with an electrical motor or internally driven by the machine shaft. The fans must follow strong requirements regarding noise. Well-dimensioned fans not only reduce the procurement costs, they also allow lower power consumption.

The cooling medium takes the losses produced in the machine and removes them. The most widely available cooling medium is air, and accordingly, air is used for most of electrical motors and generators. Hydrogen under pressure reaches a significantly better heat transfer coefficient. The hydrogen must, however, be enclosed in a pressure safe casing due to the risk of the production of explosive gas. Large turbo generators are cooled with hydrogen. Demineralized treated water is very effective for stator cooling, however a water-cooled stator is difficult to construct and to operate, so water is used only for very large generators. Instead, oil is more commonly used for the cooling of transformers.